Airpel filters

Machinery such as pumps and valves can be broken by grit, metal fragments, etc., while nozzles and heat exchangers have narrow construction that could easily become blocked. This equipment is expensive to repair / replace and the cost of downtime could be crippling, so the installation of a strainer ensures that the primary equipment is protected from any unplanned outage.

Airpel OV Simplex Filters

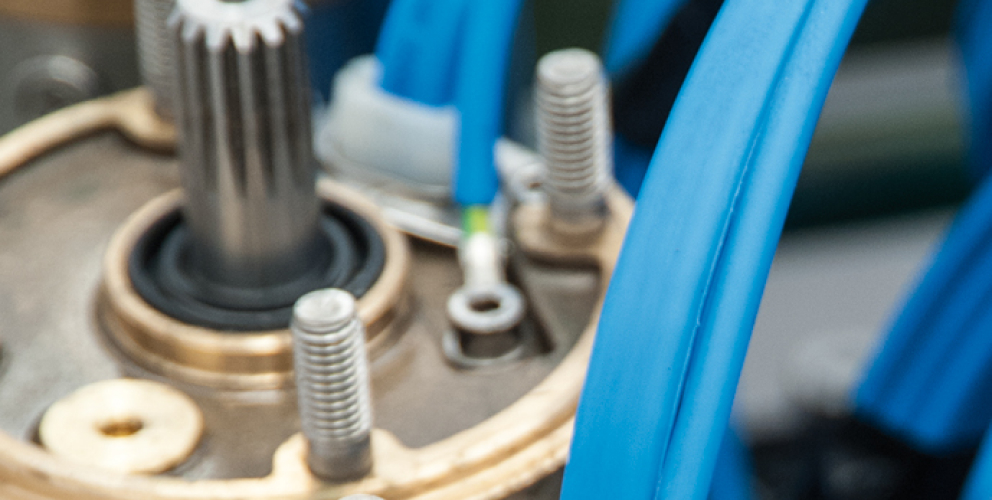

Airpel OV single and multi basket filters are designed for the removal of solids from liquid flows. The OV series is used in liquid handling installations where the flow can be interrupted for short periods to allow the removal of the basket for cleaning. All Airpel basket filters are of cast construction and house high quality stainless steel cylindrical baskets. The design allows quick and easy access to the baskets, so they can be cleaned and re-used, helping reduce operating costs and controlling debris levels.

Airpel OW Duplex Filters

Airpel Series OW dual basket filters are designed for the removal of solids from liquid flows. The filter is of cast construction and incorporates two chambers each containing a high quality stainless steel cylindrical basket. In operation flow is diverted from one chamber to the other without interruption by turning the filter handle which rotates dual cylindrical cocks delivering the fluid into the appropriate chamber. Offering a duty/standby arrangement, the basket contained within the standby chamber can be removed, cleaned and replaced ready for the next changeover making it ideal for use in liquid handling installations that require continuous flow.

Optional equipment of OV Simplex and OW Duplex Filters

- Heating Jackets

- Air vents

- Differential Pressure Indicators (DPI)

- High temperature / pressure options

- Exotic basket materials available

- Magnetic basket inserts

- DIN sensors to provide remote high DP signal

- OW Duplex Series - Pressure equalisation lines

Airpel SCF Self Cleaning Filters

Self-cleaning filters are designed specifically to provide efficient filtration for liquids, including those of high viscosity, requiring continuous filtration without interruption to the flow during the cleaning process. There is no operator contact with the process fluid. High quality stainless steel elements are highly effective in removing contaminant particles as small as 25 micron (μm). The filter is available for either manual or fully automatic electric or pneumatic operation. The range of optional control devices makes it particularly suitable for continuous processes and for service with high contamination levels.

Optional equipment of SCF Self Cleaning Filters

- Heating Jackets

- Manual, Electric & Pneumatic drive options

- Manual, Motorized & Fully automated control options

- Remote signalling

- Stainless Steel (std), Stainless Steel Hardened or Plastic blade options depending on process

- Explosion proof (ATEX) specification available on request