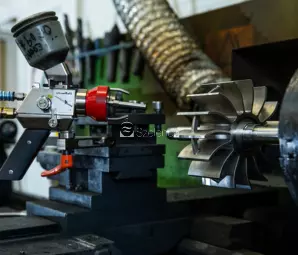

Metal spraying

We undertake the repair of metal parts with metal spraying and ceramic spraying. In our factory, we carry out cold metal spraying, primarily working with ceramics (aluminum oxide), stainless steel or chrome oxide materials. During the procedure, worn parts are repaired by creating ceramic layers.

Related Documents, Links

Wear caused by bearings, seals and O-rings becomes easily repairable, so it is exceptionally suitable for repairing of different spare parts such as shafts, rings, alternating rods and other rotary parts. Metal spraying is a cost-effective option against production and replacement of the worn spare parts.

Metal spraying procedure serves two purposes: not only worn surface is being repaired, but a much harder, more wear-resistant layer is applied to the damaged surface of the damaged spare part than the original material of construction. Beside repairing the damaged surface service lifetime of the repaired spare part can be extended. 70-72 HRC surface hardness can be achieved on the sprayed surface.

The most common tasks and parts for metal and ceramic spraying surface treatment in our plant:

Shaft metal spraying

- Pumps

- Gear box shafts

Repair of electric motor shafts

Scraper blade heat-exchanger shafts, shaft ends

Refurbishment of other spare parts

- Piston rod

- Filling machine rods

- Any other type alternating rods

- Rings, mechanical seals

- Rotary joints

- Shaft sleeves