Dynamic balancing

About dynamic balancing

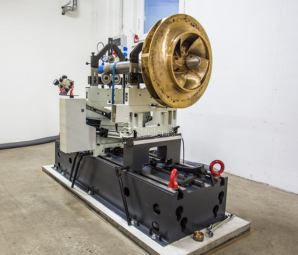

When repairing rotary machines it is essential to have the rotating part in balance to avoid premature failures. We do both static and dynamic balancing in our workshop on rotors received from any region of the country. Size, part type and the nature of the failure determines whether static or dynamic balancing is needed. Determining dynamic failiure such as 180° mass difference is not possible with static balancing. In contrast to this, during dynamic balancing this type of error is measurable and as a result it can be repaired.

Furthermore in case of working with massive and wider rotors, e.g. rotors of electric motors or larger pump impellers dynamic balancing of the rotary parts. Balancing procedure is done according to the relevant standards. With our dynamic balancing instrument we can accept rotating parts between the following limits: weight is maximum 700 kg, bearing supporting distance is maximum 1500 mm and the diameter of the rotor is not bigger than 1850 mm.

Most common balancing tasks:

Balancing pump impellers and complete rotors

Balancing electric motor rotors

Balancing fan impellers and complete rotors

Decanter centrifuge bowl and scroll balancing

Balancing of couplings

We grant our customers six months of warranty for the balancing works made in our workshop.

To view our other service activities, visit our Service homepage!

To view our other service activities, visit our Service homepage!