Dry vacuum systems

About dry vacuum systems

The dry vacuum system is perfect for your application if the process media cannot mix with auxiliary fluids.

When should you use dry vacuum systems?

- Well-controlled medium or deep vacuum typically 1 to 50 mbar

- Service liquid is not available or there is no way to dispose of contaminated liquid

- Ambient temperature has less of an influence

- Efficiency is important

- Quiet operation is required

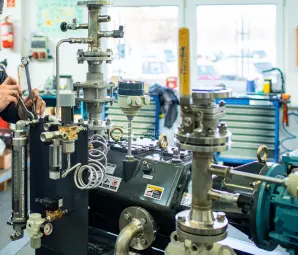

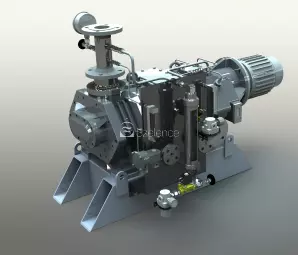

What components do dry vacuum systems consist of?

The screw vacuum pump is the central element of the system. It also includes all auxiliary equipment and instruments required for a seamless connection to the surrounding process.

Our vacuum systems are available with standalone PLC control and VFD.

Our vacuum systems are available with standalone PLC control and VFD.

How do dry vacuum systems operate?

- Vacuum is created by a Hybrid Combined Variable Pitch screw pump. The special screw design improves the exhaust performance and efficiency using a large pitch on the intake side while decreasing pitch on the exhaust side. The spindles do not come into contact with each other so there is no friction or wear. The PEEK coating protects the surfaces of the pump in contact with the medium against chemical impacts. A mechanical seal on the suction side ensures vacuum tightness. The two spindles are kept in sync by precisely fitted timing gears.

- Cooling water flow is controlled so that the internal temperature is higher than the dew point of the extracted solvents. This prevents condensation.

- Administering inert gas into the gas ballast connection of the pump further reduces the likelihood of condensation. The connection can even be used for cooling by injecting liquid.

- The space between the outboard and inboard shaft seals is pressurized with nitrogen to prevent atmospheric and any outside contaminant ingress.

- Additional inert gas purge and solvent flush is also available.

- Adding PLC control, a reliable and highly efficient system can be built.

What are the specifications of the dry vacuum system?

- SVC pump with patented Hybrid Combined Variable Pitch screws

- Chemical and heat resistant PEEK coating on interior surfaces

- 110 to 2700 m3/h @ 1 mbara flow range over six different pump sizes

- 0.06 mbara ultimate pressure

- ATEX Zone 1 IIC T4 certificate

- Continuous temperature and pressure monitoring, inert gas purge, flushing functions

- Noise reduction with special machine feet and exhaust silencer is available to max. 74 dB(A)

What are the Szelence DSVS dry vacuum system’s features?

- Double the efficiency compared to similar liquid ring systems

- Up to 20% more efficient and 5 dB quieter than conventional screw pumps

- Exhaust gas cooler than that of conventional screw pumps

- Lower coolant consumption due to lower outlet temperature

- No wear whatsoever in the pump housing so performance remains constant over time

- Possibility of layout and design to suit individual needs, even interchangeable with the existing system

In which industries can the Szelence DSVS dry vacuum system be used?

- Pharma

- Food & Beverage

- Chemical industry

- Electronics and semiconductor manufacturing

- Steel industry

In which processes can the Szelence DSVS dry vacuum system be used?

- Distillation

- Refining

- Freeze drying

- Impregnation

- Degassing

- Central vacuum

- Solvent recovery