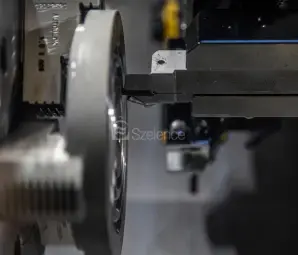

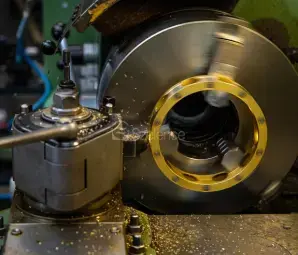

Turning

Turning is an essential technological process in the production of precision parts. In addition to the latest CNC lathes, our machinery also includes traditional turning equipment.

Related Documents, Links

What materials do we specifically undertake to work with?

Metal turning

We can use the vast majority of metals as raw materials, but we can also turn several special, unusual materials.

Stainless steel CNC turning

Precision CNC turning allows you to take advantage of the excellent corrosion resistance and durability of stainless steel, while ensuring accurate and reliable machining. This technology is particularly important in industrial and medical applications where high quality is essential.

Aluminium turning

Our specialty is the production of aluminum CNC parts. Custom aluminum machining enables the creation of precision parts that are essential in many areas of industry. The use of CNC technology ensures excellent quality and a short production time, so the final result always meets the highest expectations.

Hastelloy C machining

Hastelloy is a special nickel-chromium-molybdenum alloy known for its exceptional corrosion resistance and strength at high temperatures. The manufacturing process is particularly challenging, as it is an extremely hard and heat-resistant material that requires special tools and techniques for precise machining. Due to the high toughness of the material, traditional turning tools wear out quickly, so advanced CNC tools are necessary for accurate and efficient machining.

Plastic turning

Plastic turning is becoming more and more important in industry, as the manufactured parts can be used in a wide range of applications. The plastic parts - such as the use of PEEK and POM is particularly advantageous, as they are light, corrosion resistant and flexible.