Liquid ring vacuum systems

About liquid ring vacuum systems

A liquid ring vacuum system is perfect for your application if Medium or low vacuum is required, typically 33 to 200 mbara. The process media contains liquid droplets or solid contaminants - these contaminants are well tolerated by the liquid ring vacuum pump. As there is no metal to metal contact between the housing and the impeller and the gaps are large, the vacuum pump constuctions’s cost of maintenance is low. It would be favourable to recycle the ring liquid.

What is the structure of liquid ring vacuum systems?

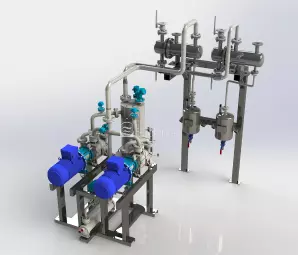

The system is centered around one or multiple liquid ring vacuum pumps. It also includes the auxiliary equipment and instruments necessary to integrate the system into the process, like a separator, heat exchanger, ring liquid circulation pump etc.

Our vacuum systems are available with PLC control and VFD.

Our vacuum systems are available with PLC control and VFD.

What is the operation of liquid ring vacuum systems?

- The liquid ring vacuum pumps uses water or another ring liquid that is compatible with the gas to be extracted. An impeller which is eccentrically positioned to the housing rotates in the pump. The pump is partially filled with ring liquid. Due to the rotation of the impeller and the resulting centrifugal force, the liquid in the housing forms the liquid ring. The pumped medium enters the space between the vanes and the liquid ring. Due to the eccentric position of the impeller, the volume between the blades varies depending on the angular position. In the suction stage the volume increases, vacuum is created and the gas is pulled in. During the compression phase, the volume decreases, the gas is compressed and leaves through the outlet nozzle.

- The liquid is constantly draining from the pump during the operation. A mixture of gas, vapor and liquid droplets leave through the discharge port of the pump. In the case of a once-through system, the liquid flows directly into the drain system, but polluting or wasting water. Szelence is committed to environmentally friendly solutions, therefore we recommend closed circulation systems.

- In a closed circulation system, droplets are pulled out of the stream in a separator tank and from there the pump recirculates the ring liquid, while also cooling it through a heat exchanger.

- The stable operation of the pump system requires the control of liquid level, vacuum and temperature values, therefore our systems also include necessary transmitter and control elements.

- By using PLC control a reliable and highly efficient vacuum system can be built.

What are the specifications of the liquid ring vacuum system?

- Travaini liquid ring pump with a final vacuum of 33 to 200 mbara (using water @15 °C)

- 40 to 3500 m3/h flow range

- Single flow (open), partial recirculation, full recirculation (closed) fluid system constructions

- 2 or 3 liquid ring pumps can be built in within a system in a parallel arrangement

What are Szelence liquid ring vacuum system’s features?

- Durable, low maintenance system

- Can handle dirt and contamination

- Low operating temperature

- No friction, no wear surface in the vacuum space, constant performance even in long run period

- Possibility of layout and design to suit individual needs, even interchangeable with the existing system

- Also available in ATEX Zone 1

In which industries can the Szelence liquid ring vacuum system be used?

- Pharma

- Food & Beverage

- Sewage treatment

- Power

- Chemical industry

In which processes can the Szelence DSVS dry vacuum system be used?

- Distillation

- Refining

- Drying

- Impregnation

- Central vacuum

- Solvent recovery

Our range of liquid ring vacuum systems consist of two designs:

- Szelence LRVS liquid ring vacuum system is a complex, all-in-one, liquid-ring vacuum system that is usually designed and built to meet individual needs.

- Szelence LRVSM liquid ring vacuum system is a compact and cost-effective version of the LRVS system. It is based on the smaller monoblock Travaini pumps.