Grinding and Lapping

After turning an milling, surface roughness develops on the mechanical materials. When grinding, we get a much finer, more balanced surface.

Related Documents, Links

We apply the following procedures for grinding materials

Surface grinding

In the surface grinding process, the purpose of grinding is to create precise, flat surfaces from different materials, ensuring the desired dimensional and shape accuracy.

Internal grinding

During internal grinding, the internal holes are precision machined, which we carry out in-house within our own competence.

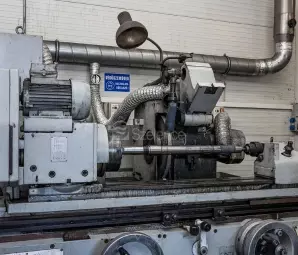

Cylindrical grinding

In this process, we perform precise machining on the outer surface of the cylindrical parts, during which the quality of the grinding is of paramount importance. High-quality cylindrical grinding ensures the required dimensional accuracy and the desired surface roughness, increasing the lifetime and performance of the components.

Lapping

Lapping is an innovative process that ensures the perfect flatness of surfaces. During lapping, we work with special tools and materials to eliminate even the smallest roughness and achieve a lasting result.