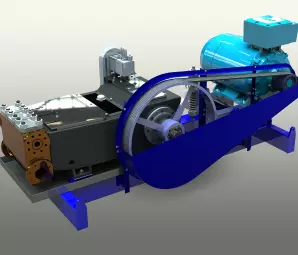

Pump units

About pump units

Our unique, customized pump units are available based on any pumping technology. In accordance with nowadays trends, we undertake the delivery of complete pump units which can adjust to the specific needs of our customers, even in explosion-proof design. The support provided by our experienced team of engineers covers the entire life cycle of the product, starting from the on-site survey, to planning, production, commissioning and after-sales.

In which industries can our pump units be used?

Practically everywhere where it is necessary to pump liquids and gases, primarily:

- Chemical industry

- Oil and gas industry

- Pharmaceutical industry

- Food and cosmetics industry

- Agriculture

- Municipal drinking water and wastewater treatment

- Machine manufacturing, metallurgy

- Laboratories

What are the features of our pump units?

- Designing application-optimized custom systems

- Close cooperation with the customer from project initiation to completion.

- Stable service background.

- Engineering support and services.

Main pump types in Szelence pump units:

- Centrifugal pumps

- for any general, chemical or oil industry application

- available in accordance with API 610 / ISO 13709, ISO 2858, ISO 5199 standards

- High-pressure plunger pumps

- water reciprocation pumps,

- high-pressure cleaning,

- high-pressure liquid transport,

- ATEX design available

- Diaphragm pumps

- for highly viscous chemicals,

- for food products and cosmetics,

- ATEX and FDA compliance available

- Dosing pumps

- pulsation-free diaphragm,

- plunger,

- gear,

- ATEX and FDA compliance available

- Hermetically sealed, leak-free canned pumps

- where zero emissions are allowed,

- for toxic and other highly hazardous substances,

- for high temperature fluids,

- available in ATEX and API 685

Full product support - from design to operation

Thanks to our dedicated team of engineers, product support is provided throughout the entire life cycle of the equipment we manufacture:

- Site survey activities

- Machine support structure design (fixed, grouted baseplates, specially arranged units, skids and other portable units etc.)

- Selection and design of mechanical seals and systems, including containment and monitoring solutions

- Selection and design of power transmission (clutches, belt drives, motors, gear drives, etc.)

- Instrumentation

- Pump control and monitoring system design

- Site inspection and supervision activities during the construction or installation of the pump system

- Commissioning of pumps and auxiliary systems

- Pump & drive shaft alignment on site with the service team

- Products conforming to ATEX, FDA, API, or ISO standards upon request

- Operator training