Statiflo Static Mixing

About Statiflo

Worldwide Leaders in Technology and Application of Static Pipe Mixers, Open Channel Mixers and Enclosed Duct Mixers.

Statiflo is a world leader in the development and application of static pipe mixers, inline static mixers, channel mixers, duct mixers, gas dispersion systems, flow conditioners and associated technologies with thousands of customers in every process industry in over 80 countries.

Our headquarters are located in Macclesfield, Cheshire, in the north west of England.

Through experience, innovation and inspiration Statiflo continues to strengthen its reputation as the world leaders in the design and manufacture of static mixers, channel mixers, gas dispersion systems and associated technologies.

Statiflo is a world leader in the development and application of static pipe mixers, inline static mixers, channel mixers, duct mixers, gas dispersion systems, flow conditioners and associated technologies with thousands of customers in every process industry in over 80 countries.

Our headquarters are located in Macclesfield, Cheshire, in the north west of England.

Through experience, innovation and inspiration Statiflo continues to strengthen its reputation as the world leaders in the design and manufacture of static mixers, channel mixers, gas dispersion systems and associated technologies.

Related Video

Main industries:

- Water treatment

- Desalination

- Wastewater treatment

- Oil, Gas and Petrochemical industries

- Food and pharmaceutical

- Pulp and paper

- Continous Process Industries

- Brewing Industry

- Marine Industry

Main Products:

- Pipe Static Mixers

- Channel and Dust Static Mixers

- Gas Dispersion System

General industrial static mixers

Statiflo General Industrial Inline Static Mixers suitable for all process industries supplied with fixed or removable mixing elements.

Usually supplied with SO or WN flanged end connections, but could equally be supplied with plain or weld prepared ends. Screwed/threaded end connections available for smaller sizes.

Optional flanged or threaded injectors and sampling points. Optional heating/cooling jackets

Can be supplied in all commercially available metallic materials.

Channel and Duct Static Mixers

Statiflo’s Channel and Duct Static Mixers are revolutionising the design and operation of water and wastewater treatment plants.

Statiflo Series 900 Channel Mixers rapidly achieve a high degree of mix with extremely low headloss in very short lengths.

Complete mixing in the channel is possible, achieving a low CoV, over a wide range of flowrates. With headlosses of just a few millimetres feasible, gravity flow is an option, eliminating the expense of pumping, saving not just capital costs, but ongoing maintenance and energy costs too.

Statiflo Channel Mixers can be installed in new treatment works or easily retrofitted into existing installations, even when flooded and live. The modular design concept, based on the STMC mixing elements, allows wide variations in aspect ratio (height/width) suitable for square or nearly square channel sections, narrow deep channels and wide shallow channels. Independent trials have established that the STMC concept is the most efficient of all known commercially available static mixers.

Applications include:

- Raw water blending

- pH control

- Rapid coagulant addition

- Polyelectrolyte dosing

- Residence time control

The high efficiencies and benefits of the channel static mixer apply to any scale, the largest installed to date is 7m wide x 5m deep, handling 7 tonnes/sec of water.

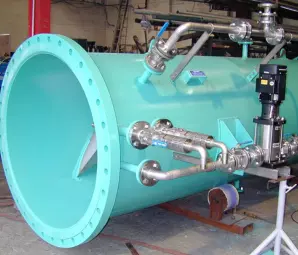

Gas Dispersion Systems: Custom Designed, Engineered and Built

The Statiflo Gas Dispersion System (GDS) is a new concept for simultaneous mixing and mass transfer.

The Statiflo GDS is designed to overcome the difficulties associated with the use of a single static mixer. The system uses two different mixers, the first, in a sidestream, to form small gas bubbles and the second, in the main line to provide contact time and efficient mass transfer. As the gas bubbles are formed in a constant velocity sidestream, the gas bubble size is constant and independent of any variations in the main liquid flow.